Return shipping fees are the customer’s responsibility.Įlectronic /Downloaded Products & Online Learning Courses: These items are not eligible for return.

#Lap splice table full

Printed / Hard Copy Products: The full and complete returned product will be accepted if returned within 60 days of receipt and in salable condition. For a listing of and access to all product errata, visit the Errata are not included for collections or sets of documents such as the ACI Collection. Document DetailsĬhapter 4-Development of high relative rib area bar reinforcement in tensionĬhapter 5-Lap splices of high relative rib area bar reinforcement in tensionĪppendix A-Recommended supplement to ASTM A615/A615M for high relative rib area barsĪny applicable errata are included with individual documents at the time of purchase. The lapped sections of contact lap splices are wired to-gether.

#Lap splice table code

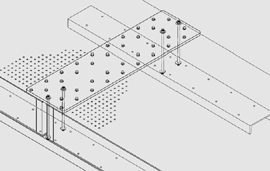

There are two types of lap splices: contact lap and non-contact lap splices (see Figure 1a and 1b). The analyzer code was then used to read the input data and perform the lapping pattern generation, cutting pattern generation and optimization operations. This helps transfer loads properly throughout the structure. Keywords: bar reinforcement bar ribs bond development length high relative rib area lap splice length. lap splice is when two pieces of rebar overlap to form a continuous reinforcement. Commentary provisions begin with an “R,” such as “R1.1.1,” and are shown in italics.

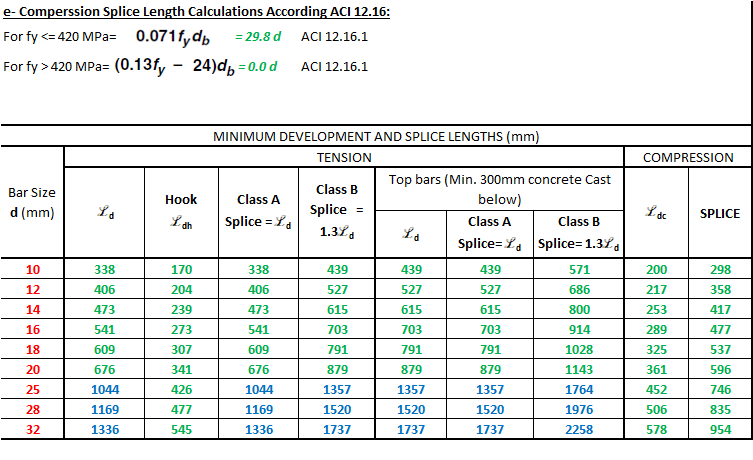

AASTHO and BNBC design codes also exhibit same splice length for 36 mm. A commentary to the mandatory language portion is provided for additional information. Lap splice length (ls) increases when the bar diameter (d¬b) increases. To assist the user to incorporate the information into a legal document, the relevant portion of the document is written in mandatory language. When such requirements are applicable for a project, the user may incorporate the information in this guide into a legal document however, this guide is not an ACI standard and shall not be adopted by reference into legal documents. This identification is based on expected strain demands in the rebar and splice assemblies. This guide provides recommended requirements to determine tension development and splice lengths for high relative rib area bar reinforcement, which are not in commercial production in the U.S. Splices are classified into three functional categories, Ultimate, Service, and Lap splices, as shown in Table 1.

0 kommentar(er)

0 kommentar(er)